Dr Melissa Kozul, a mechanical engineer in the Faculty of Engineering and Information Technology, is fascinated by the unique, aerodynamic properties of shark skin. Over recent decades, scientists have been inspired by shark skin microstructure, which reduces skin friction drag on sharks as they swim through the ocean, to engineer micro surfaces that optimise the performance of aerodynamic systems, such as compressor blades in jet engines or aeroplane fuselages.

Dr Kozul is one of a pioneering team of University of Melbourne researchers, led by Professor Richard Sandberg in the Fluid Mechanics group, working at the cutting edge to improve aerodynamic performance with innovative surface textures, or to accurately represent the roughened surfaces of the high-pressure turbine blades downstream of the combustors in a gas turbine.

In a jet engine, for example, the high-pressure turbine blades are exposed to the harshest environments in the engine, in terms of pressure and temperature, while rotating at extremely high speed. These blades are initially smooth, but become roughened over their lifetime, which significantly changes the turbulent air flow over the blade.

Thus, the work of this team allows better predictions of the actual efficiency and lifetimes of these blades.

The team is seeking to improve understanding of turbulent flows and ultimately the efficiencies of gas turbines, which are used for propulsion in aeroplanes, and with fuels like natural gas to produce electricity for the grid.

The team has been awarded a series of Innovative and Novel Computational Impact on Theory and Experiment (INCITE) computing grants since 2021 by the US Department of Energy, to conduct their research on leadership-scale supercomputers. They are presently conducting simulations on the world's most powerful supercomputer, Frontier. The hours are being used to simulate the turbulent flow within jet engines, in a collaborative research project with General Electric Aerospace.

They are the only Australian team being supported by an INCITE grant at present, making their computational fluid dynamics simulations the largest of their kind run by any Australian research group.

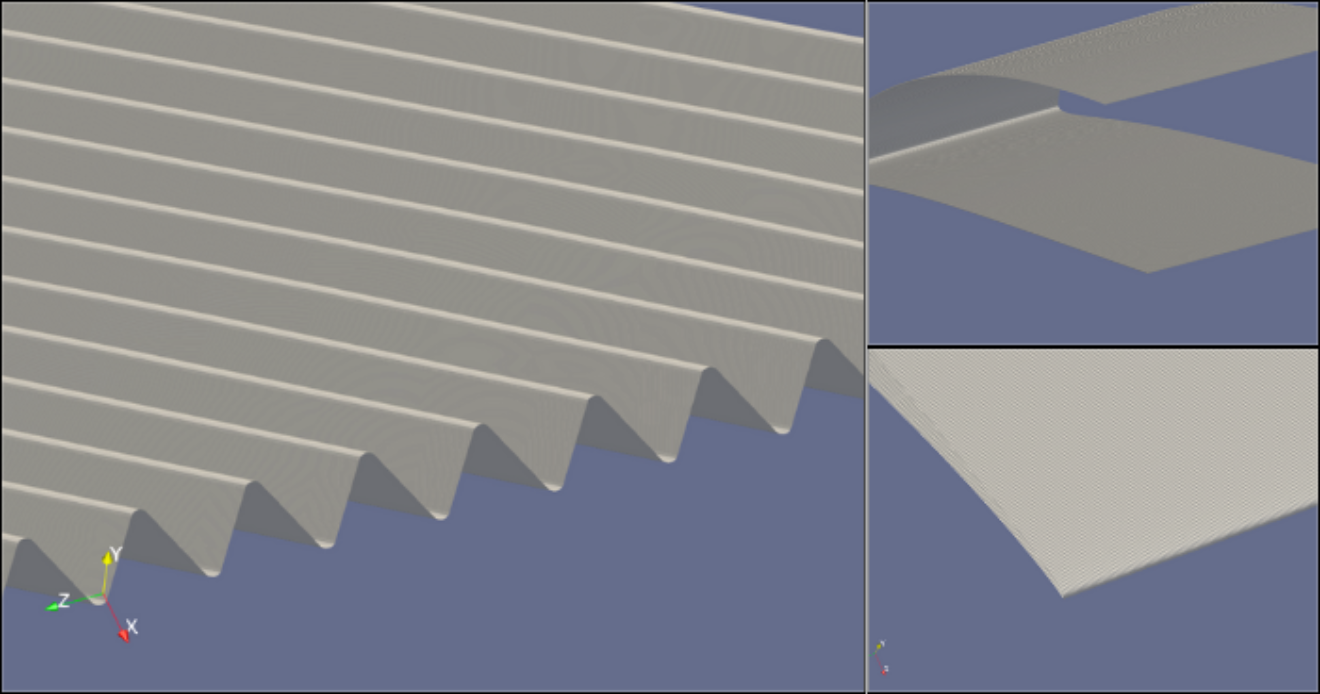

Dr Kozul’s research focuses on the potential of blade-surface micro-textures or 'riblets,' to minimise the airflow resistance or drag on gas turbine compressor blades, which are primarily used in the energy generation and aviation industries.

Dr Kozul explained that, contrary to common assumptions, engineered roughness at the micro-scale of a gas turbine blade surface can improve power output.

"Usually in engineering contexts, we want aerodynamic surfaces to be as smooth as possible, for example, gas turbine blades, aeroplane fuselages and ship hulls. But if we look to nature, neither shark skin nor birds’ feathers are smooth at the microscale."

“When air or water flows over microscopic ridges on a surface, turbulent structures, which cause drag, are lifted away from the surface, creating a sort of ‘cushion’ of fluid. That is, they serve to reduce the contact between turbulent flow (wind/air) and the surface, which can cause less friction between the surface and the fluid to lower the drag. Under certain conditions, this could result in a better compressor, and therefore, overall gas turbine efficiency.

“Just like in nature, however, these engineered surfaces need to be microscopic to be effective.

"Our research involves complex simulations at the microscale. This requires substantial computational power for adequate resolution (like a high-resolution photograph), so all the turbulent flow physics is captured.

“The Frontier supercomputer, and its predecessor Summit, allow us to simulate the effects of riblets on the compressor blades in gas turbines, amongst other research questions."

Dr Kozul’s interest in engineering stemmed from a desire to contribute to the transition to more sustainable energy sources.

"Engineers face difficulties in reducing carbon emissions for gas turbines, yet it is essential that we persist since there is no viable alternative for large, long-haul aeroplanes. Gas turbines are also commonly used in baseload power production. Although natural gas is a cleaner alternative to coal, it still significantly contributes to carbon emissions," she said.

“Gas turbines are flexible in terms of the fuel they burn. Therefore, we are also exploring ways to use cleaner fuels, such as hydrogen, which would yield zero carbon emissions. Since hydrogen burns hotter and faster than natural gas, we need to try to understand how burning hydrogen might affect the safety and longevity of gas turbine blades.”

The aviation industry is already testing shark skin riblet insights to reduce drag on the outside of aeroplanes, with Japan airlines piloting riblet paint on two Boeing 737 aircraft, announced in 2023. Dr Kozul is hopeful that riblets will one day be used on aeroplane engines.